Working with epoxy resins at home - Do you need a good ventilation and respiratory protection?

Working with epoxy resins at home - Do you need a good ventilation and respiratory protection?

Whether you are an experienced resin user or just want to try this versatile material for the first time, you have probably considered if it is safe to use and let the epoxy cure at home, where you do not necessarily have a good ventilation setup. Do you need a mask? Or a respirator? Is it okay to leave the project with uncured resin in your living room, or can it cause health issues?

This article will explore the safety of using epoxy resin at home, focusing on ventilation and respiratory protection needs, the significance of VOCs, and the unique approach Nerpa Polymers takes to ensure user safety.

What are the VOCs, and why VOC free resin ≠ safe to breathe without protection

As you are probably already aware, epoxy resin brands like stating that their products contain zero volatile organic compounds (VOCs). What are VOCs anyway? Read in our blog. In short, it is a group of chemicals that can quickly evaporate from the bulk of liquid because they have a high vapour pressure. Not all of them are bad; for example, the fragrance industry uses VOCs all the time to adjust the longevity of the scent. In the resin world, VOCs in the form of solvents for viscosity reduction and specific properties adjustment were common in the industrial epoxy grades. Regulations in North America have started to become stricter and are aimed toward a more environmentally friendly manufacturing approach, forcing manufacturers to limit the use of VOCs. Nowadays, most epoxy resin products are advertised as having low or zero VOC content, and this is often perceived as the certificate of safety of the product. Unfortunately, even though the absence of the solvents or other easily evaporating components in the epoxy resin should logically mean that you can use the product safely without a mask and sufficient ventilation - in fact, it really does not.

The following information does not pertain to Nerpa products but is essential for understanding the broader industry context.

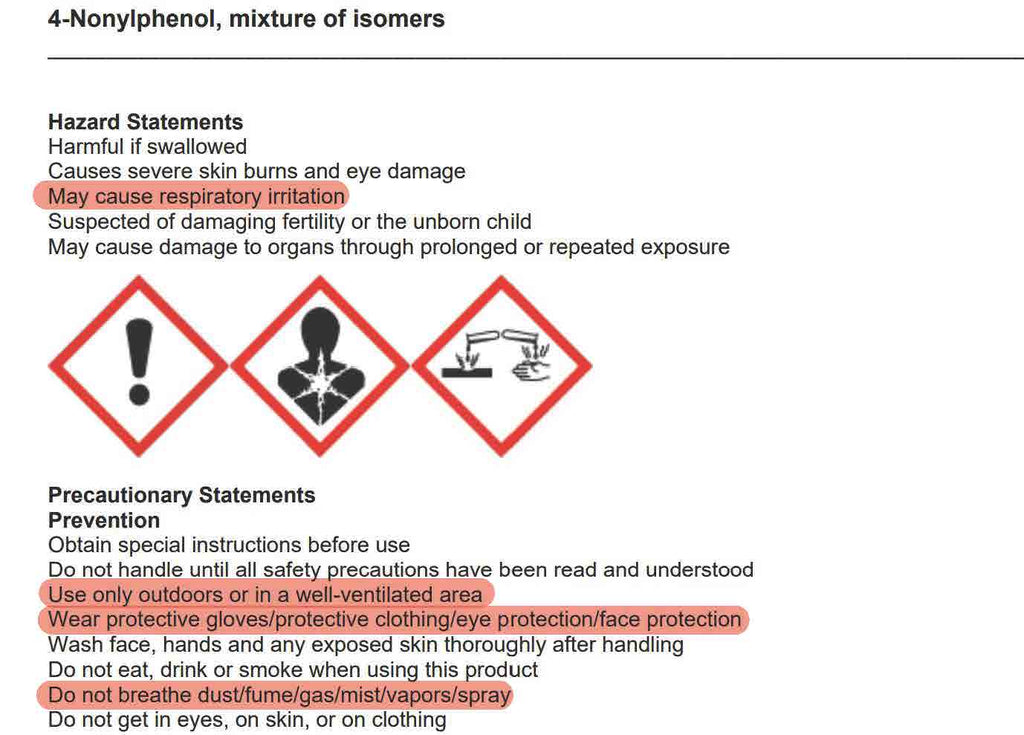

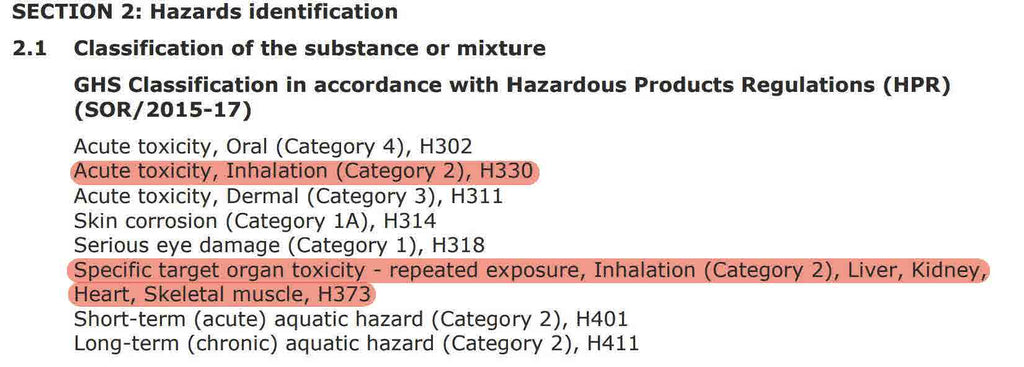

The absence of VOCs does not mean that you do not need ventilation because of the chemicals that are often used in epoxy manufacturing, which are not VOCs but still pose a danger if inhaled. For example, many “art epoxies” or resins marketed for home use are 1:1 (one-to-one) mixing ratio two-part epoxies. Part B, or hardener, is often produced with three components: the reactive part that goes into the reaction with the resin (part A), the filler component (nonylphenol), and the accelerator (so epoxy cures within 24 hours) such as (scary chemical name incoming) AMINOETHYLPIPERAZINE or AEP in short. These names are provided as an example, but there are other chemicals of similar nature, such as DIMETHYLDICYANE (DMDC), and others that are often used in DIY epoxies. None of these chemicals are VOCs, but they can still harm you. What should you know about them?

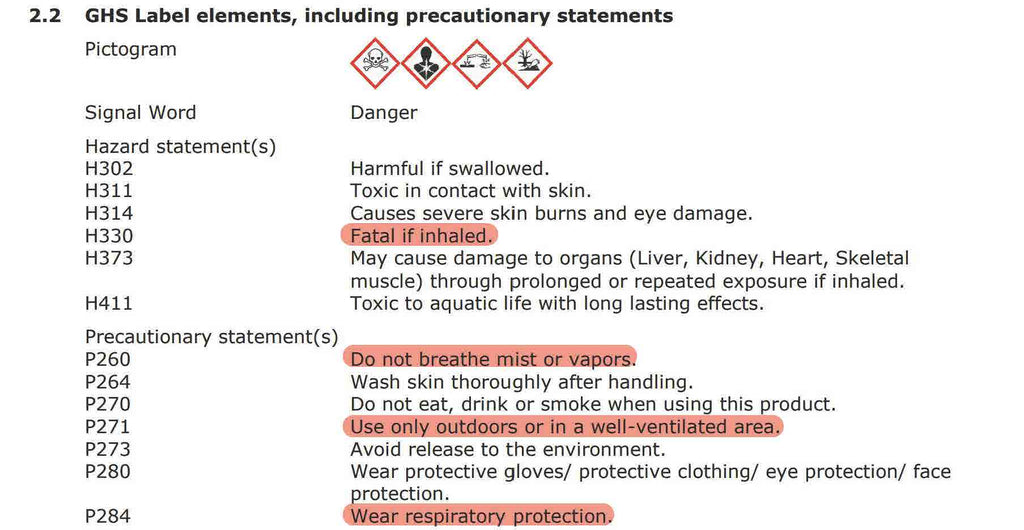

Here are the statements from the safety data sheets of the chemicals we considered:

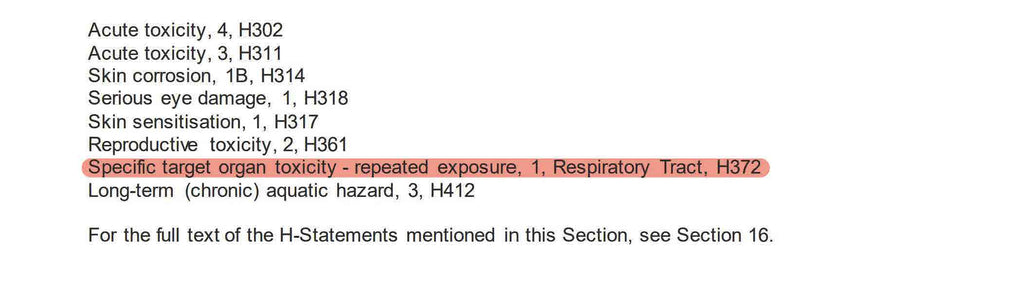

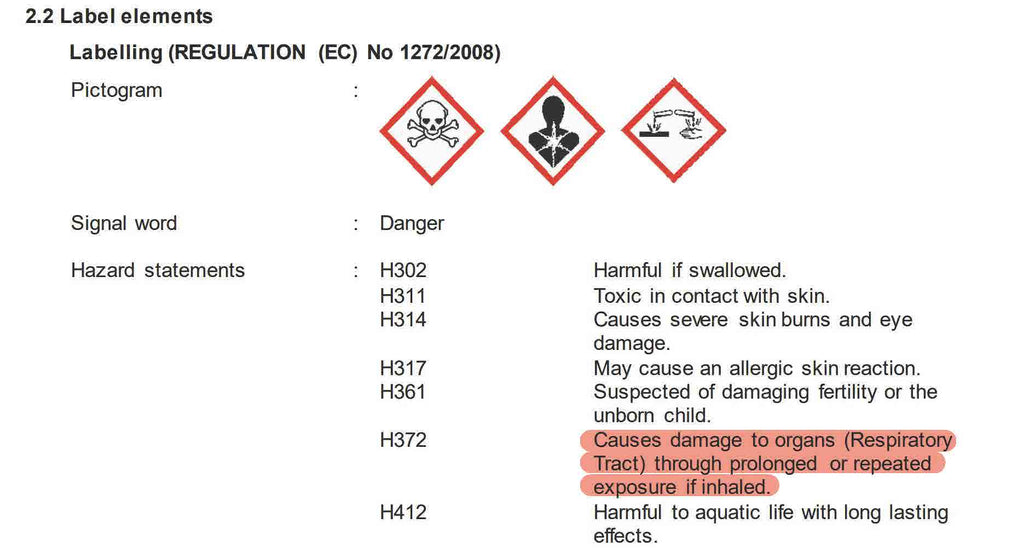

AEP (AMINOETHYLPIPERAZINE):

The information above was taken from safety data sheets accompanying these materials before they were combined as an art epoxy. Unfortunately, unless you have an analytical chemical laboratory, there is no real way to know which chemicals your resin contains. Resellers often do not even have the safety data sheets for the products they offer, but if they do, there is no guarantee that the information is accurate and up to date. For instance, the presence of the AEP compound might not be listed in the safety data sheet of the resin brand you are currently using, though its presence is highly likely. This discrepancy can arise for several reasons. Manufacturers may choose to protect their proprietary formulas by not disclosing detailed composition information, invoking their right to keep these "trade secrets" formulas and have a right not to disclose exact information about the composition of their products; in other cases, it could be negligence - new brands pop up on the marketplaces every day, and the capacity of the agencies like Health Canada to verify the product compliance with the safety standards is limited.

Some of these statements might seem alarming and even scary! However, please remember that Safety Data Sheets provide information for individual compounds. Epoxy resin consists of numerous components, so the overall effect is somewhat mitigated when parts with higher danger levels are combined with those that have lower danger levels. At the same time, you can clearly see that these compounds are unsafe to inhale.

Hence, the conclusion is obvious - you should have adequate ventilation and a respiratory tract protection system if you work with resins from other brands at home. It is also not recommended to leave uncured resin in the living space. Remember that prolonged and/or repeated exposure increases the risks of respiratory issues over time.

WHAT ABOUT NERPA's PRODUCTS?

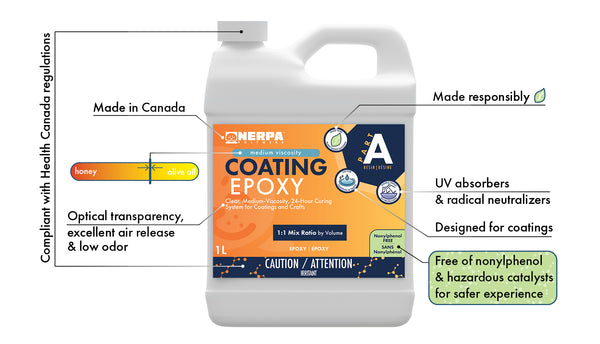

With all this in mind, you might wonder about Nerpa Polymers' approach to making our products. Let's delve into how our products stand out. We had the option to use the same set of chemicals that other manufacturers use, but we decided to formulate our resin systems with safer alternatives. We formulate our Coating and Casting resins in a way that they can be used at home by inexperienced users. What exactly does it mean in more detail?

- We do not use any of the chemical components that are associated with respiratory hazards, such as AEP, nonylphenol and others.

- We always encourage our customers to use proper personal protective equipment, such as gloves, long sleeve shirts and goggles (epoxy is always an irritant; you should refrain from working with this material without gloves).

- We always communicate to our customers the actual dangers associated with working with our materials, and they are clearly listed on our packaging.

Certain high-performance resins in our portfolio that are used in composites may pose respiratory risks due to their material composition. These resins can achieve exceptional heat resistance only by utilizing special-grade materials. Nerpa Polymers offers these specialized resins for custom orders and categorizes them as "for industrial use only." Should we make these products available on our website, we will provide detailed safety precautions to ensure their safe use.

We recommend using respiratory and eye protection when finishing your project with sanding and polishing steps. Inhaling uncured resin microparticles may cause allergic reactions. It generally takes resin 24-72 hours (depending on the type) to be ready for sanding, but reaching full cure state might take seven days or longer.

We hope that you find the information in this blog post useful and help you make an educated product choice for your next resin project. At Nerpa Polymers, we are committed to providing not just safer products, but also the knowledge you need to use them with confidence. Whether you are a beginner or a seasoned creator, we support your journey towards beautiful, safe, and sustainable crafting experience.

Please share your thoughts and feedback in the comment section. We will be happy to answer your questions!